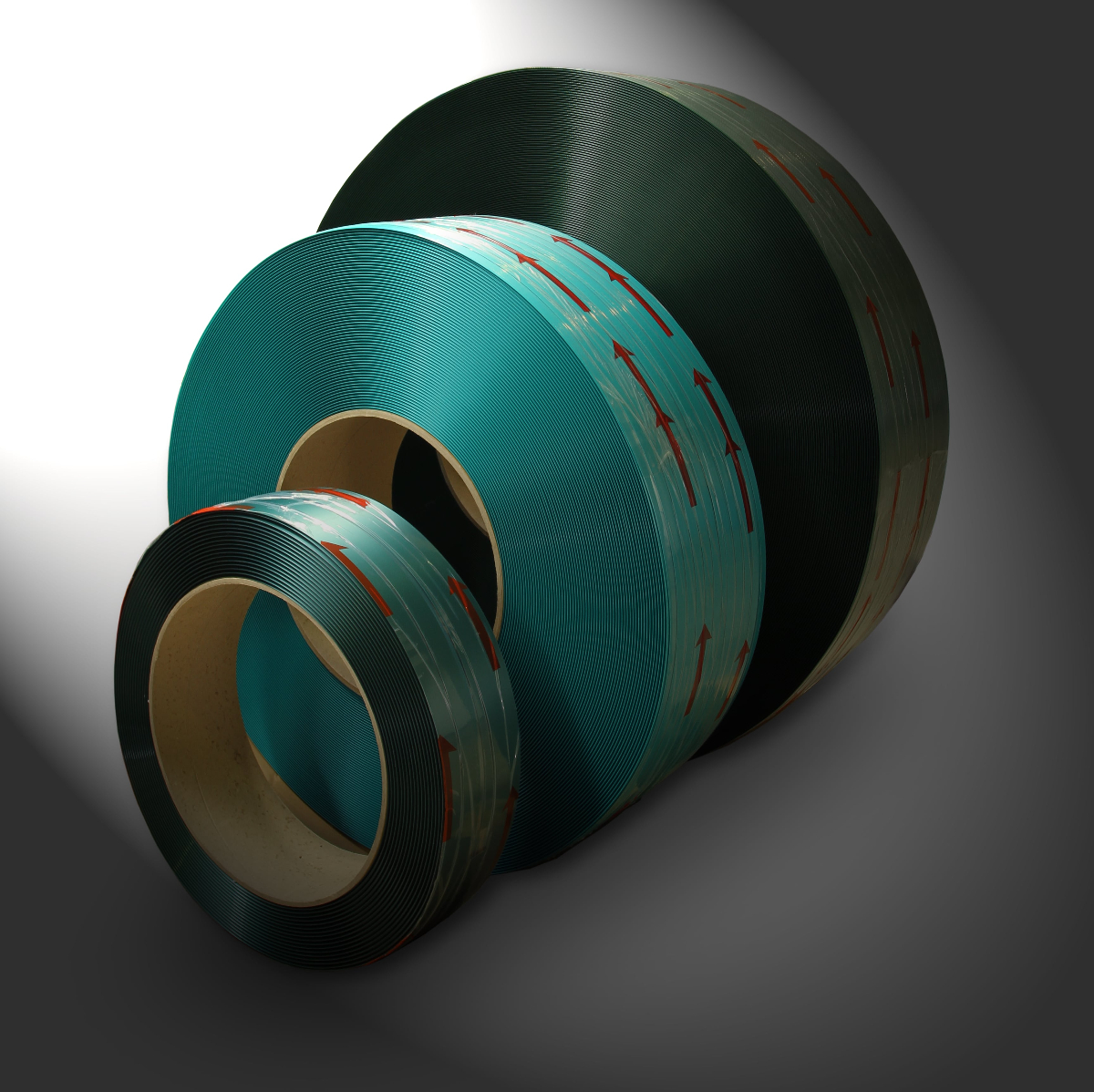

It was not too long ago that plastic strapping became available on the market. Up until that time steel strapping was the normal standard used by packaging companies to secure loads and pallets. It has since then spread throughout the market and is now the preferred way to secure items for shipping. Plastic strapping is easy to use and readily available on the market. It has opened up a lot of options and improved the way shipping items is traditionally done today.

Why Plastic Strapping is Preferred over Steel Strapping

Plastic strapping has four elements to it that make it the preferred choice of shipping and packaging companies.

- Tension is the resistance of force that happens as the strap is being pulled in a certain direction. It is like having two forces pulling in opposite directions of each other along a straight line. As this happens tension is created. The tension causes the strap to stretch.

- Elongation is the result of applied tension. At some point the strap will reach its maximum stretching point and will either need to return to its original size or it will snap.

- Recovery happens when the pressure is released and the strap pulls back attempting to return to its starting size. Whatever item is caught in the middle becomes trapped within the strap. Here you have a secure load. The strap holds everything in place.

- A working range of a plastic strap is the maximum stretch that can be applied to the strap before it snaps or tears. When this happens the effectiveness of the strap is no longer valuable and must be disposed of.

Security and Safety are Extremely Important

When straps are applied correctly, they keep the load secure and safe. They are secure because the load does not shift during transport, and they are safe because it is harder to steal something that is tied down. Plastic strapping is widely used on the market today. The tension that the strap has holds items tightly in place and does not allow them to move around. The tools that are used to secure the straps to the load are easy to use and allow the operator to control the amount of pressure being applied to the strap. This allows the operator to get the tension of the strap just right so it is as tight as it can be.

Switching at the Right Time

The time to switch from steel strapping to plastic depends on a few factors. It will depend on when the money is available to update machinery from steel to plastic. It will require the purchase of additional resources such as the plastic strapping and storage space. It may seem daunting at first but it is possible to make the switch.

It is recommended that to switch from steel strapping to plastic that a company should use at least one full pallet of steel strapping a month. This indicates that the volume and finances are available to make the switch. The amount of steel that comes per container is less than what comes in a plastic strapping container. So right away the company is saving money because it is getting more material for its dollar.

Making the move is easier than you think. At Fastpak we strive to deliver the best kind of packaging to your door. We focus highly on the supplies and equipment of the manufacturing and distribution markets. We want your business to succeed because it is using only the best materials for shipping and packing. Call us today at 770-423-0795 or email us and let us help you make the switch to a better material for your business needs.